In modern healthcare, the best distribution relationships do not announce themselves. When things work, teams barely notice the moving parts. Orders arrive when expected, the right items are matched to the right paperwork, and questions are answered without a long trail of emails. That calm feeling is not luck. It comes from small, consistent standards that hold up every day, including during busy weeks when schedules shift and pressure rises.

This article stays on the operational side only. It does not include medical claims, clinical guidance, or detailed product information. Instead, it focuses on what procurement and operations teams can actually evaluate: reliability over time, record clarity, traceability discipline, communication quality, and the practical systems that reduce friction across hospital workflows. For many teams, the decision becomes clearer when they assess whether an endovascular device supplier can deliver these standards without creating extra work for the people receiving, reconciling, and supporting orders.

Consistency is built into routines, not promised in meetings.

Many organisations sound impressive at the start. What matters more is how they perform across ordinary weeks. Reliable service looks like stable delivery planning, accurate order fulfillment, and a low rate of preventable exceptions. It also looks like a calm handling of small issues. When a mismatch occurs, a mature operator does not wait for complaints to stack up. They respond quickly, fix the immediate problem, and tighten the step that caused it.

A dependable service model is usually easy to explain. Good teams can describe how orders are checked, how packing accuracy is protected, and how exceptions are escalated and resolved. The explanation does not need fancy words. It just needs enough detail to show the work is process-led, not dependent on last-minute improvisation. When reliability comes from routine controls, it stays steady even when staff is busy and timelines tighten.

Documentation is operational control, not admin work.

In healthcare, records are not “extra.” They are part of how organisations protect accountability. When documentation is complete and consistent, internal checks move faster, and uncertainty stays low. When paperwork is missing, unclear, or hard to match to a shipment, the burden shifts to staff that must pause and confirm basics that should already be clear. That pause is where time disappears, because one missing detail can trigger follow-ups across logistics, procurement, and internal stakeholders.

Strong record habits reduce workload across departments. Receiving teams can reconcile deliveries without chasing clarifications. Procurement teams can close order cycles faster because fewer gaps need to be corrected after arrival. Internal stakeholders can access what they need without turning simple questions into long threads. Over time, clean documentation becomes one of the clearest signs that a distribution model is built for real hospital operations, not just for ideal conditions on paper.

Traceability should work quietly in the background.

Traceability tends to get attention right before audits. That is too late. In daily operations, traceability should be routine and easy to validate. If someone needs to confirm details later, the information should be accessible without searching across inboxes, portals, and disconnected files. The goal is not to create more steps. The goal is to make sure the right identifiers are captured consistently so verification does not become a time sink.

High-performing service teams design workflows that make key details hard to miss. They do not rely on memory or manual clean-up after the fact. This matters because healthcare environments have predictable pressure peaks. When workloads rise, systems either protect accuracy or expose weak points. Traceability that holds up during pressure is one of those quiet standards that prevent small issues from becoming bigger operational problems later.

Communication quality prevents disruption more than speed alone.

Hospitals and clinics do not benefit from vague reassurance. They benefit from clear updates that support planning. When availability shifts or delivery windows change, the difference between a minor adjustment and a disruptive scramble often comes down to communication. A dependable team communicates early, explains what is confirmed, and states clearly what is still being checked. That clarity helps staff decide what needs action now and what can wait.

Accountability matters just as much as timing. When something goes wrong, who owns the issue? How quickly does the team respond with a real plan? How often does the customer need to repeat the same context to different contacts? Strong service operations reduce handoffs, keep ownership clear, and avoid the slow drift that happens when a problem is passed around without a decision-maker. Good communication is not “more messages.” It is fewer messages that carry clearer information.

Portfolio-based categories require coordination, not complexity.

Many hospitals work with portfolio-based categories that involve multiple manufacturers and product lines. That structure can work well, but it increases the need for coordination. Without disciplined coordination, portfolio coverage can create mixed messages, inconsistent records, and confusion about what belongs to which order. In Switzerland, endovascular portfolios are often organised across multiple manufacturers in a filtered catalogue, so clean order matching and dependable records matter even more.

The best distribution experiences make portfolio coverage feel organised. Availability updates connect cleanly to order records. Documentation stays consistent. Pending items remain visible, so teams do not lose time verifying basic status. The goal is not to flood procurement teams with options. The goal is to keep operations predictable even when the product landscape is multi-brand and frequently updated, and even when order volumes shift during peak periods.

Digital visibility should reduce follow-ups, not add steps.

Digital tools matter only when they reduce uncertainty. Teams want visibility into what is confirmed, what is being prepared, what is in transit, and what records are tied to each order. When visibility is reliable, planning becomes easier. When it is not, staff fills the gap with emails, calls, and cautious assumptions that multiply across departments. Over time, those follow-ups become a hidden cost, because each one pulls attention away from more valuable work.

The best digital support fits existing workflows. It does not force new routines just to access basic facts. It reduces the number of check-ins needed to confirm routine details and helps exceptions get resolved faster. When digital visibility works well, teams spend less time chasing status and more time coordinating what truly needs coordination. The improvement is subtle but real: fewer surprises, fewer gaps, and fewer moments where someone has to “hunt” for a clear answer.

Evaluate performance during exceptions, not only during calm periods.

Any organisation can look strong when conditions are stable. The real test appears when something changes. A delivery window needs to shift due to site constraints. A shipment is delayed. An order needs quick clarification. These moments reveal whether the service model has depth or relies on improvisation. The calm response is the signal, not the stressful moment itself.

A mature operation handles exceptions with a steady method. It communicates early, responds clearly, and keeps the customer informed without creating noise. It also learns from repeated issues and adjusts internal steps instead of treating each disruption as unrelated. Over time, that discipline reduces the frequency of problems, not just the pain of each individual incident. This is also where long-term trust grows, because staff stop budgeting extra time for “just in case” follow-ups.

Onboarding and continuity protect long-term outcomes

A common mistake in selection is assuming day-one responsiveness will remain identical once the relationship becomes routine. This is why onboarding matters. A well-run partner sets expectations early around ordering flows, documentation handling, points of contact, and escalation routes. When these pathways are clear, issues get resolved faster because the customer is not guessing how support works, and internal teams are not improvising on the process.

Continuity is equally important. When contacts change too often, context gets lost, and hospital staff end up repeating the same background information. Stable support protects continuity through clean internal records, consistent communication channels, and internal handoffs that do not become the customer’s problem. Quiet stability often looks like fewer repeated explanations and fewer “starting over” moments. When continuity is protected, service quality feels steady even as people change behind the scenes.

Conclusion

The quiet standards of high performance are rarely dramatic. They show up in predictable deliveries, clean documentation, and traceability that hold up when workloads rise. They show up in calm communication during exceptions and in systems that reduce follow-ups instead of adding new steps. When these standards are in place, procurement teams spend less time managing uncertainty and more time supporting stable operations across the healthcare environment, even when the pace increases and timelines tighten.

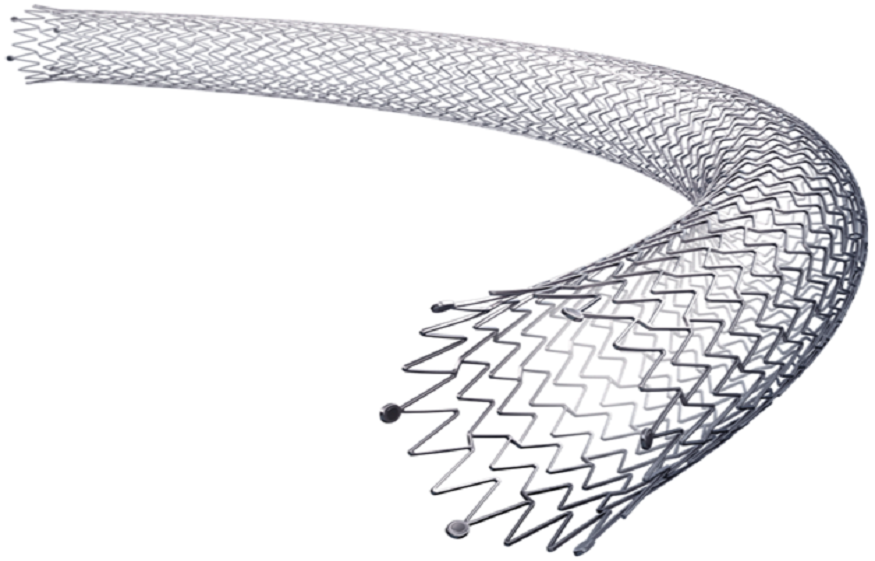

For Swiss hospitals and clinics that value this kind of consistency, Nexamedic supports healthcare environments with dependable service, professional guidance, and expert support, while keeping coordination and documentation disciplined across day-to-day operations and supporting access to an endovascular device portfolio that can include categories such as stents, coils, catheters, and embolics.

FAQs

Q 1. What should procurement teams prioritise when selecting a distribution partner for regulated environments?

Ans 1. Prioritise consistency and record discipline. Look for stable order accuracy, predictable delivery planning, and documentation that arrives complete without repeated requests. Review how exceptions are handled, including escalation of ownership and response clarity. A strong partner reduces follow-ups and keeps internal workflows calm, even during busy periods.

Q 2. How can a hospital assess documentation quality without creating extra work?

Ans 2. Ask how records are delivered and reconciled in routine cycles. The best indicator is whether documentation is consistent, easy to match to shipments, and available without reminders. If teams regularly chase missing files or clarifications, the documentation process is not operationally strong, and it will create ongoing admin load.

Q 3. Why does communication style matter so much in healthcare distribution?

Ans 3. Because unclear updates create delays and extra follow-ups, strong communication is early, specific, and honest about what is confirmed versus what is still being checked. It also includes clear ownership, so issues do not bounce across multiple contacts. This reduces operational stress and helps teams plan with confidence.

Q 4. What is a practical way to test service strength before committing to long-term?

Ans 4. Evaluate how the organisation handles small exceptions early on. Watch for early notice, clear timelines, consistent documentation, and a single point of accountability. Also, note whether the same issue repeats or whether internal steps improve quickly. Reliable performance during minor disruptions often predicts stability later.

You may also like

-

Healthcare Outsourcing to the Philippines: Achieving Revenue Cycle Excellence Through Strategic Partnership

-

Top Reasons to Source Medicines from Indian Pharma Exporters

-

Role of Free Zones in Supporting Pharma Export Businesses in UAE

-

How to Set Sustainable Nutrition Goals Without Dieting

-

How to Find a Reliable Dietitian Online in India